Custom Solutions

We create unique value with you:

Quality

Packaging excellence in every detail:

Engineering & Design

We are packaging problem solvers:

Sustainability

Sustainable focus:

BUSINESS UNITS

Custom Packaging Solutions

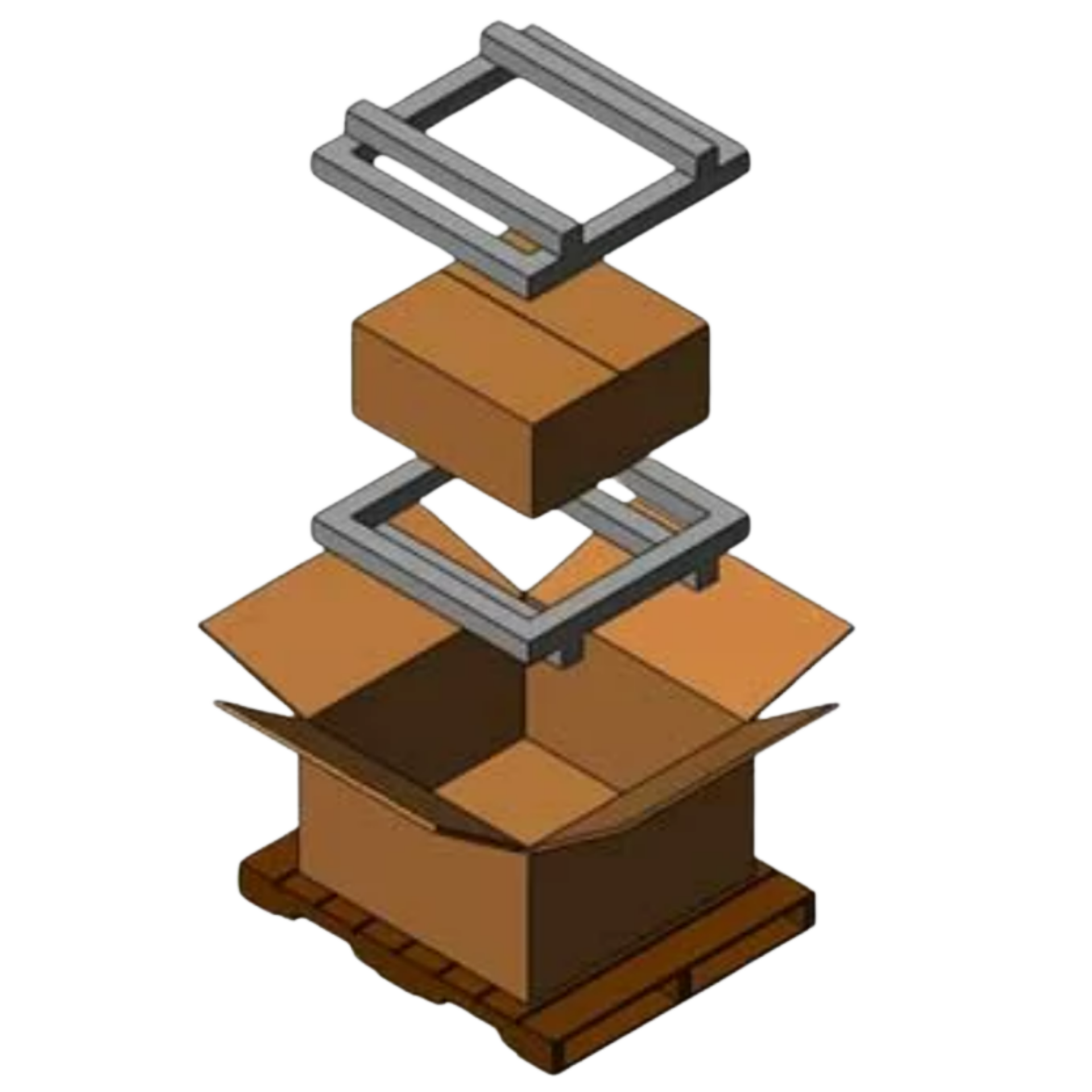

Utilizing a material neutral approach when engineering packaging solutions, we provide larger, sophisticated organizations with custom manufactured protective packaging components and multi-material assemblies, improving performance and driving out cost.

CORNER POSTS AND CLAMP PROTECTION

Blending innovative engineering and advanced manufacturing with over 25 years of custom design experience provides the foundation for meeting each customer’s individual needs.

Engineered

Solutions

Our Solutions Development teams, made up of Engineering, Design, Supply Chain, and Project Management, utilize a collaborative solution development process:

- Identify an opportunity and gather all the information

- Move ideas and concepts into drawings and specifications

- Create samples, design tooling, perform testing, and run various trials as needed

- Launch production quickly and efficiently.

We are always solving problems with you in mind. Whether it is:

- Collaborating on the development of an integrated multi-material assembly to protect your product

- Creating a supply chain solution to reduce your risk and lower your costs

- Designing a custom profile for your paper tubes to increase the strength and performance

Your Individual needs drive the solution development process through implementation.

Strategic

Locations

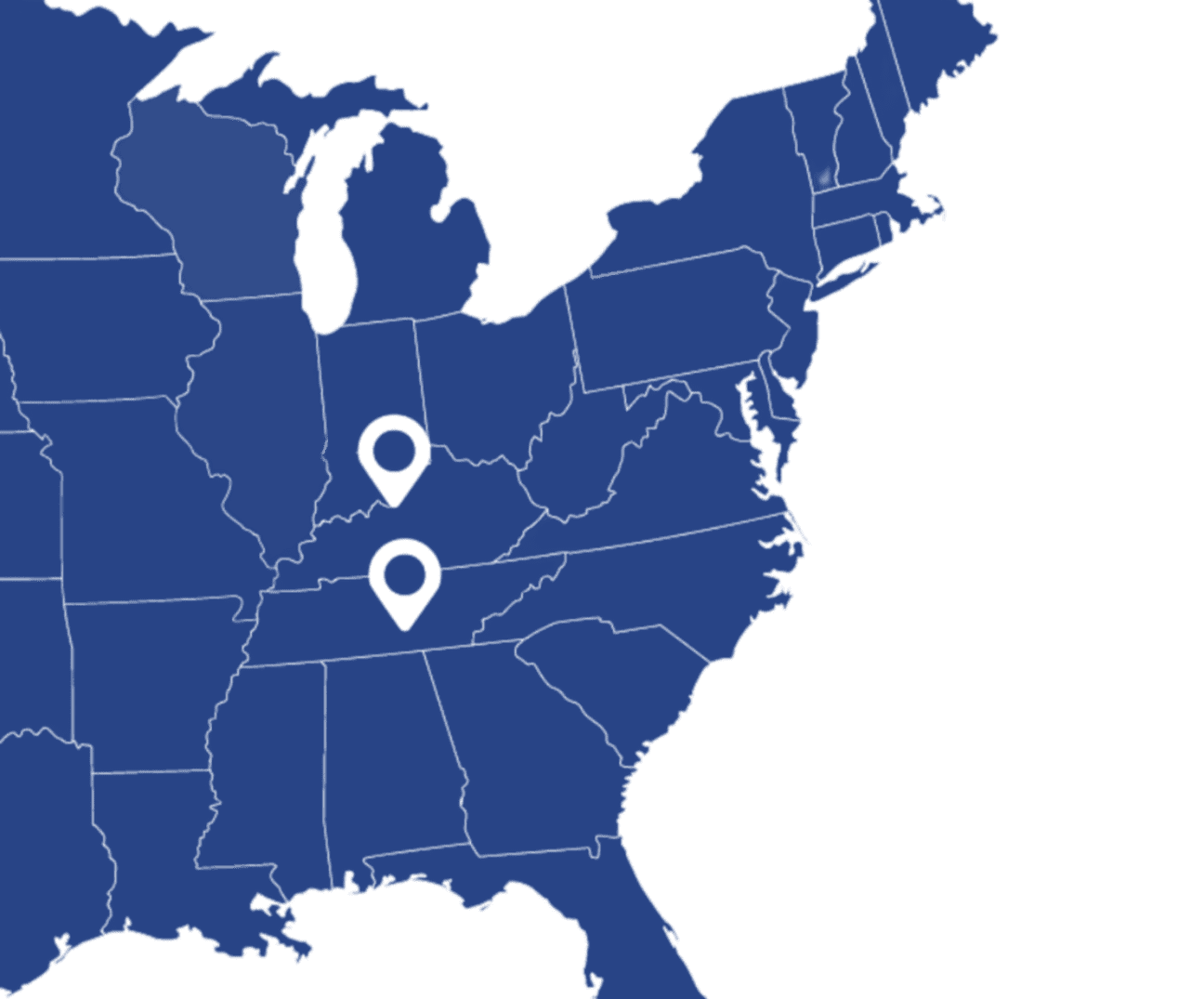

Centrally located in the Mid-South, we are positioned in the heart of U.S. industrial manufacturing.

With a climate that supports business and growth, we continue to leverage the benefits our communities offer.

Low Cost of:

- Labor

- Property/Real Estate

- Living

- Taxes

Freedom

Statistics

PROTECTIVE PACKAGING

We have proven to be one of the best at providing protective packaging solutions to the home appliance industry for more than 20 years.

Fabricating engineered foam plastics like polystyrene, polyethylene, and polypropylene and assembling wood or corrugated paper with just the right adhesives or fasteners.

We are focused on producing material neutral solutions for today’s packaging problems.

FABRICATION

We will use the best process to generate the most value.

Fabricating packaging foams with: Computer-controlled, multi-wire contour cutters. Vertical hot-wire processing. Hot-melt adhesive. Laminating. Roll-coating. PSA. Release liner…

Re-manufacturing wood with: Multi-blade ripsaws. Package saws. Dual-head notchers with de-scramblers. Auto-feed, multi-cut band saws. Highly accurate, tight-tolerance planers. Multiple-spindle industrial boring machines…

ASSEMBLY

Over two decades ago, we started producing multi-material assemblies for protective packaging.

We currently utilize: Automated, computer-controlled assembly; collaborative, robotic production stations; high-volume, custom assembly; tight-tolerance hand assemblies with fixtures and poka-yokes…

We will use the best materials that will solve your problem with the best value. Period.

APPLIANCES

We have helped deliver more than 49 million appliances safely to their destinations.

Freedom Industries has been solving packaging problems, driving out cost, and providing component parts to the large home appliance industry for 20+ years.

We use molded and extruded foam plastics as well as exportable, heat-treated wood component fabrication, and multi-material assemblies to meet your needs.